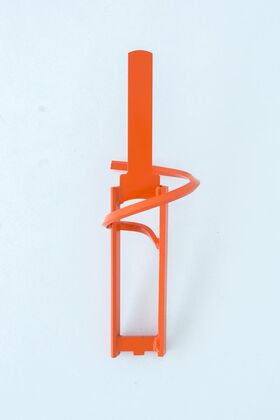

One of the elements of finishing machines that require periodic replacement is the PFT G4 / G5 BIONIK mixing helix used in PFT class G plastering stations. This part is also called whisk, volute or mixer.

The use of a shaft is recommended in the manufacture of plaster mortars of all types (cement, lime, gypsum, lime-gypsum, lime-cement, insulating, masonry, reinforcing, adhesive, sealing), as well as floor levelers (leveling and self-leveling) without admixture of fillers.

Specifications of mixing spiral PFT G4/G5 BIONIK

This detail is involved in the process of mixing mortar in the mixing chamber of plastering stations. In a technical sense, its function is to maintain the pressure of the screw pair on the finishing machines of the PFT class G class (for example: G4, G5), as well as similar devices. Its functional purpose is to feed the dry mixture into the screw pair.

1. The spiral element for plastering machines is made of special high-strength steel. This guarantees increased wear resistance, resistance to fracture and twisting, which ensures the full development of the resource and maintains the integrity of the part throughout the entire period declared by the manufacturer.

2. The standard mixing spiral PFT G4/G5 BIONIK can be easily replaced with a new one if necessary.

3. Does not have a landing protrusion for the hole in the coupling cone. Due to its absence, the replacement of the main engine is facilitated. It also eliminates the occurrence of vibration in the clutch, which in turn reduces the load on the main motor shaft.

4. Installation of a spiral on engines with old couplings is possible.

The buyer is guaranteed to receive a really high-quality and reliable part, which will ensure the uninterrupted operation of the mechanized chain for the production of finishing works.

When to change the mixing spiral PFT G4/G5 BIONIK

Despite the fact that this PFT G4/G5 BIONIK mixing spiral is made of a heavy-duty alloy, for durable and trouble-free operation of plaster systems, this part must be replaced with a new one in a timely manner. It is worth changing the part when the resource indicated by the manufacturer is exhausted.This period depends on many parameters, which in total give an understanding of the load on the part (the number of revolutions made, as well as the type and quality of the processed mortars are taken into account). That is, the resource of the part is calculated individually, as well as the timing of replacement.If maintenance of the finishing equipment is not carried out according to the schedule, and the state of all machine components, including the mixing spiral, is not monitored, a sudden stop of the system is possible. In addition to the failure of the mechanism and the need for expensive service work, this can lead to downtime of the work crew and missed deadlines.

No reviews found